Tingertech, one of the most respected and best bldc fan motor manufacturer, has taken pride in offering efficient and reliable Brushless DC Motors. Our EC motors provide a simple, efficient design that is cost-effective. They offer easy service and maintenance, high EC motor power density and easily-controlled motor speed. This EC motor model is mainly used for axial fan. Also we can custom BLDC motors to solve your unique challenges. For custom orders, please contact us so that we can learn more about your specific application.

EC motor, from Tingertech, has the characteristics of high efficiency and energy saving. Electronically commutated motors consist of brushless permanent magnet (BPM) motors with an integrated electronic control module. This precisely drives the permanent magnet rotor of an EC motor, providing more energy-efficient operation.

Models of EC Motors

| ITEM | VOLTAGE | FREQUENCY | POWER | RPM | EFFICIENCY | WS |

| YDZ16001 | 220V | 50/60HZ | 850W | 450-2000 | 85% | S1 |

| YDZ16002 | 220V | 50/60HZ | 1200W | 450-2000 | 85% | S1 |

| YDZ16003 | 220V | 50/60HZ | 1500W | 450-2000 | 88% | S1 |

| YDZ16004 | 220V | 50/60HZ | 1800W | 450-2000 | 90% | S1 |

| YDZ16005 | 380V | 50/60HZ | 850W | 450-2000 | 85% | S1 |

| YDZ16006 | 380V | 50/60HZ | 1200W | 450-2000 | 85% | S1 |

| YDZ16007 | 380V | 50/60HZ | 1500W | 450-2000 | 88% | S1 |

| YDZ16008 | 380V | 50/60HZ | 1800W | 450-2000 | 90% | S1 |

What is a EC Motor?

When it comes to motor design, engineers have three main types of choice—alternating current motor (AC motor), direct current motor (DC motor), and electronically commutated motor (EC motor).

What is an EC Motor (Electronically Commutated Motor) ? EC motors are also known as brushless DC motors, ECM motors and BLDC motors. It is direct current, external rotor type of motor in which AC voltage is converted to DC voltage by a commutator. EC stands for Electronic Commuting. EC fan motors are brushless motors whose rotors and onboard electronics are designed with permanent magnets to control the voltage and current applied to the motor. Without getting too technical, it's a brushless motor that uses AC power to run on DC voltage, combining the best of both worlds.

How does a BLDC motor work? The rotor of an BLDC fan motor is a permanent magnet and the stator has a coil arrangement. By applying direct current to the coil, the coil is energized and becomes an electromagnet. The operation of ECM motors is based on the force interaction between permanent magnets and electromagnets. When one coil is energized, the opposite poles of the rotor and stator attract each other. When the rotor is close to one coil, the next coil will be energized. This process is repeated and the rotor continues to rotate.

What are the advantages of ECM motors?

EC brushless motors are smaller than other motors and offer the same level of performance. This is because they do not rely on carbon brushes, but are controlled by an external electronic circuit board. Therefore, they provide greater controllability and higher efficiency. Therefore, unlike DC or AC motors, brushless EC motors only run when needed and do not overuse energy.

EC Motor Speed Controller

Some interesting questions may come to your mind: how do we know which coils to energize and when to energize the rotor continuously? The answer is, the electronic controller. The sensor determines the position of the rotor, and based on this information, the controller decides which coil to power.

An EC motor consists of an integrated system. It contains:

(a) Converting electronic equipment

(b) Speed control electronics

(c) Stator and DC rotor.

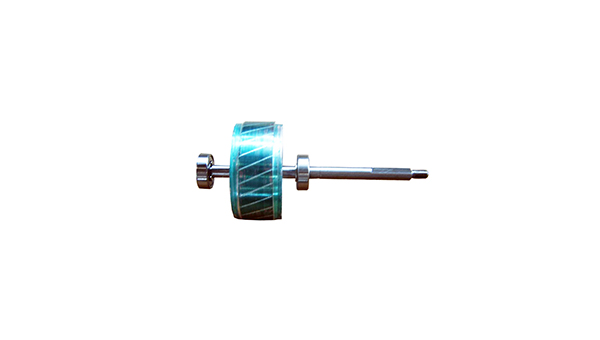

BLDC Fan Motor Structure

BLDC motor is not that complicated, referring to its structure. China brushless bldc motor from Tingertech consists of a stator and contain a rotating rotor inside, which is surrounded by pole-pieces and a bldc motor controller or called ec motor controller. All our EC fan motors comply with the appropriate International Standards as far as: ec fan motor output, bldc fan motor performance and dimensions of china ec fan motor.

Tingertech's ec motor control has high precision with high performance which is benefit from continuing development of ec motor technology team. Tingertech is proud to present Tingertech technology with low temperature rise, silent noise and low vibration. BLDC motor drivers is designed and matached by our own team, economical and high efficiency.

Electrical BLDC Motor Suppliers & Manufacturers

If you are seeking for bldc motor manufacturer or bldc motor driver factory, you have come to the right bldc motor control and china brushless bldc motor driver website. OR, if you want to know bldc motor drive, bldc motor control, bldc motor design or bldc motor price, even bldc motor diagram, please just feel free to contact Tingertech, china bldc motor suppliers, wholesale bldc motor manufacturer & supplier & factory in china.

BLDC Motor Manufacturing Processes

Tingertech has expent huge manual work, skill and years of experience to offer such a wide range of EC fan motor. Furthermore, Tingertech has dipping equipment and drying kilns with shaft heights up to 800 mm, an in-house welding shop for flexible production of special components and custom welding designs, VPI dipping equipment and experienced specialists who truly understand their processes. This is how Tingertech guarantee you the high quality, reliability and durability of china ec fan motor.

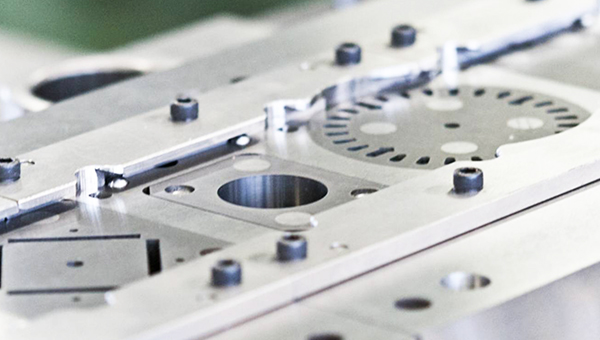

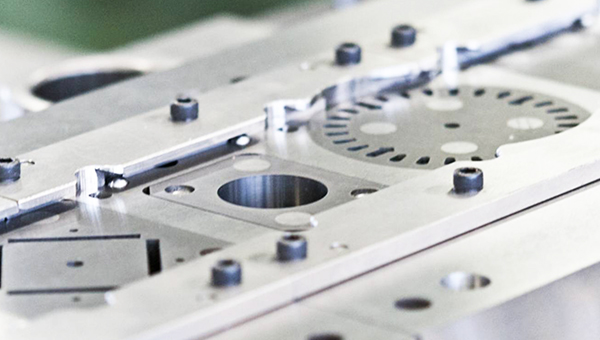

| 1. STATOR CORE & ROTOR CORE

Stator core and rotor core for fan motor from ec fan motor supplier & factory & manufacturer are built up of thin punched laminations of Silicon Steel, its stator laminations and rotor laminations are made by high speed punch machine which is invested by our own, and this plays a vital role in quality of ac fan motor. Over 10 Million press strokes per day allows output of over 100 Tons finished stator / rotor core laminations each day. |  |

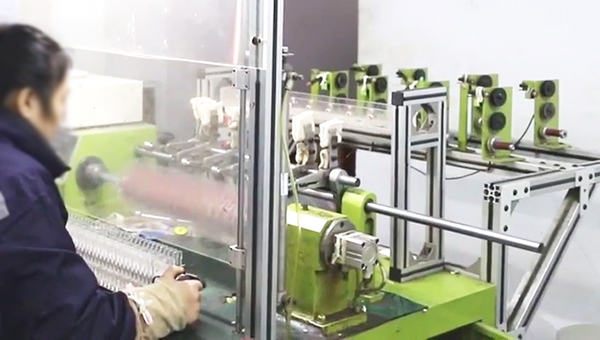

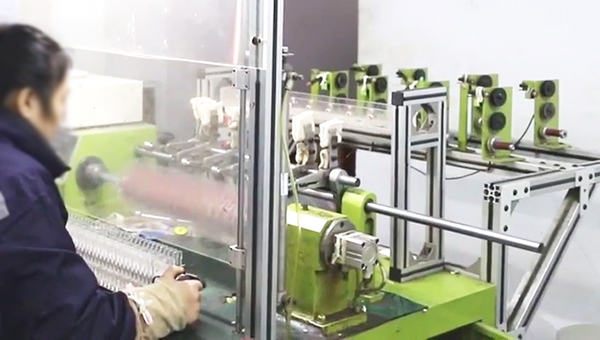

| 2. COIL WINDING

Professional in the ec motor technology, team from ec motor fan factory & manufacturer & supplier has extensive experience working with both copper and aluminium wire in various forms to provide coil winding solutions. Our broad customer base demands that we cannot only supply our standard range of emc fan motor but also have the capability to provide custom solutions to solve challenges others can't. Contact your electrical bldc motor supplier & manufacturer now! |

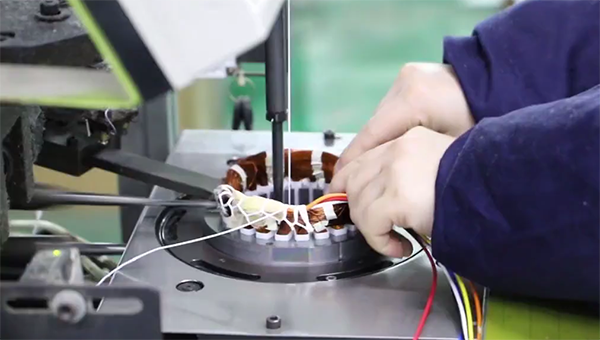

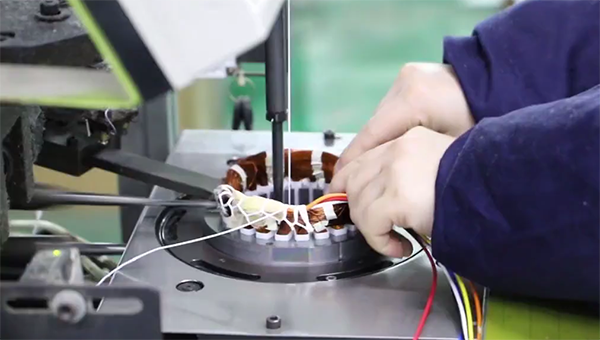

| 3. STATOR ASSEMBLY

Tingertech, best bldc motor manufacturer, has specialized in bldc fan motor technology, stator assembling can be solved by our own professonal assembly technique. It meets the requirements of series production in universal ac condenser fan motor, fan coil motor, hvac fan motor, condenser fan motor, cooler fan motor and other fan motor for ac unit. We develop and examine the entire process chain - from slot insulation to impregnating the stator and test. |  |

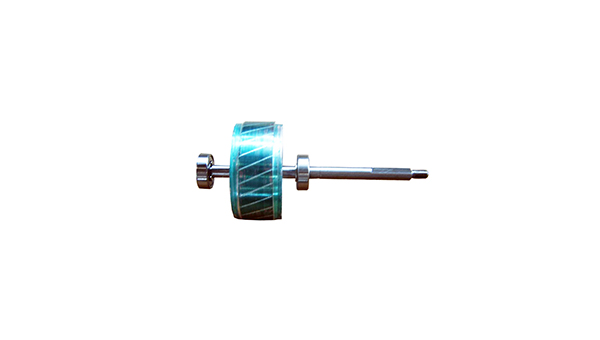

| 4. ROTOR ASSEMBLY

Rotor assembly is critical to bldc motor in a variety of industries and applications, like condenser, air conditioner, evaporator etc. Tingertech, provides high quality silicon steel material to create professional and high quality rotor assembly for all AC fan motors. A rotor assembly of ac fan motor normally includes a cylindrically shaped shaft, a processed rotor iron core and a bearing. |

| 5. FAN MOTOR SHAFT

Motor shaft is the main component in electric fan motor. The size of the shaft significantly affects the torque in fan motor. In addition to the need to mount the rotor and a variety of attachments, like bearing, the model of the motor shaft is based on the cooling concept selection of the electric device. Tingertech, bldc motor manufacturers & suppliers always offer you high quality shaft as air conditioner fan motor parts. |  |

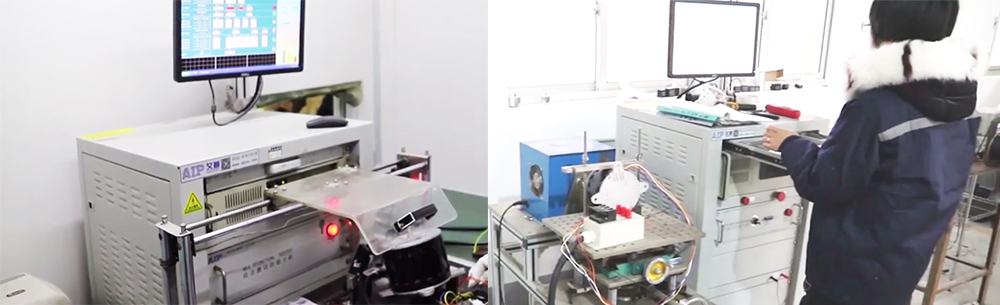

| 6. MOTOR ASSEMBLY & TESTING

Motor assembly includes assembling stator assembly, rotor assembly and end cover assembly with front cover. Testing of china electric bldc motor from low noise bldc motor supplier & factory, Tingertech, cover the whole areas from stator insulation test, electronic integrated test bench for winding inserting, motor integrated test bench, motor performance test, noise test and appearance detection through to dynamometer for high performance fan motor testing. |

Routine testing and type tests for all EC Motor

Why Choose Us?

As a prominent and leading wholesale bldc motor manufacturer, condenser fan motor suppliers & factory from china, Tingertech is willing to open worldwide market by agency. Be our agency, you can extend your business fast for your fan motors at the competitive price, stable qualtity and excellent after service. Contact your bldc motor manufacturers & ec fan motor supplier to get bldc motor price now!

24/7 After Service Availability

As a BLDC motor factory & manufacturer & supplier, Tingertech offers our customers further important plus points except focusing on fan motor quality. One of our focal points is the fast delivery of bldc motor with bldc motor controller - including special designs.

Flexible machining from our ec fan motor factory, manufacturer & supplier allows us to achieve exceptional response times. Tingertech's customers around the world appreciate our fast delivery service. Try us out! Team of experts will help you to find the right emc fan motors for your application.

24-hour emergency hotline

Tingertech provides a 24-hour hotline for our bldc motor customers. You can use it to reach us around the clock in the case of a pressing operational disruption. With Tingertech, you can depend on an bldc motor manufacturer & factory & supplier who can supply bldc motors with various voltages and outputs even outside normal working hours - all around the world.